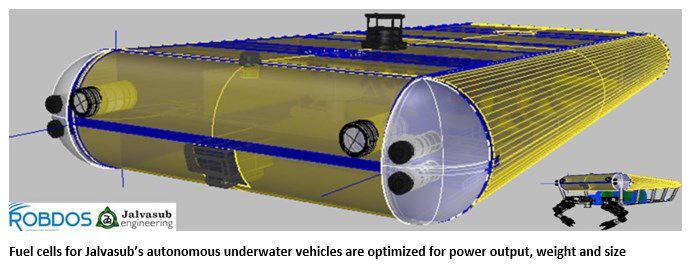

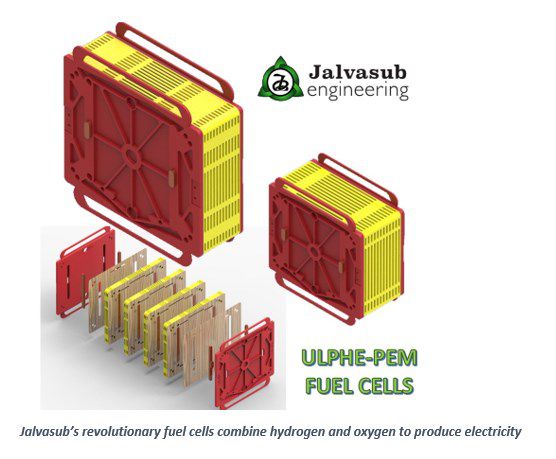

Providing revolutionary power generation and propulsion systems is the focus for JALVASUB Engineering based in Las Rozas de Madrid, Spain. JALVASUB’s compact electrical propulsion “HYCOGEN” system generates electricity using proprietary Ultra-Low Platinum Content and Higher Efficient Proton Exchange Membrane “ULPHE-PEM” fuel cell technology. The system reduces costs, weight and volume, providing higher power density than conventional systems. Founded in 2017, the high-tech company produces electrical autonomous surface and underwater vehicles propelled by hydrogen and ULPHE-PEM fuel cells.

The compactness of the ULPHE-PEM Fuel Cells is a result of its innovative design. This design requires significantly less platinum due to its high-efficiency proton exchange membrane fuel cells. The smaller, more-efficient power-generation system, which combines hydrogen as a fuel and oxygen electrochemically to produce electricity, is being implemented into JALVASUB Engineering’s marine vehicles with application in the civil, security and defense areas.

Creating a “digital twin” using Solid Edge

For the design of their marine vehicles, propulsion and power-generation systems, JALVASUB Engineering’s engineers are using Solid Edge. “With Solid Edge 3D CAD software, our team can work together more efficiently than ever before,” said JALVASUB Engineering founder and CEO, Juan Alvarez. “Synchronous technology allows us to quickly model all of the HYCOGEN system’s components. We can easily see how they connect and interact with each other.” Juan continues: “One of the most important reasons to select Solid Edge, was how easy is the transition from 2D CAD to 3D CAD with synchronous technology. Also having the support at all times of Prismacim, our local Solid Edge partner. Prismacim delivers the advice and the training we need.”

By designing their complex parts and assemblies in Solid Edge using synchronous technology, JALVASUB Engineering utilizes their designs’ “digital twins” throughout the entire product development lifecycle. “Integration of the fuel cell and propulsion components into the marine vessels is much easier with Solid Edge,” Juan said. “It allows us to reuse data and designs and gives us the ability to customize vessels and propulsion systems.”

Optimizing the design

With Solid Edge, JALVASUB leverages the digital twin throughout the entire product development process. They also utilize Simcenter FLOEFD™ for Solid Edge. Fully embedded in Solid Edge, Simcenter FLOEFD enables JALVASUB to move flow simulation early into the design process. “We could maximize utilization of oxygen and hydrogen and achieve minimum pressure loss in the fuel cell,” Alvarez said. “With the powerful analysis tools, we have increased the fuel cell’s efficiency by more than 10%. We also reduced platinum content by 10 times, decreasing overall weight and volume to 30% of the original design.” FLOEFD allows JALVASUB to avoid costly physical prototypes, reducing costs and improving durability.

Recognition, partners and future possibilities

In 2017, JALVASUB Engineering’s HYCOGEN system was selected as a “New Highly Innovative Product” by the Galician Innovation Agency’s Blue Ocean Innovation 4.0 Accelerator Program. This program is designed to accelerate specialized projects in the maritime sector. In addition, in 2019, JALVASUB was awarded the Technological SME Seal of the Spanish Ministry of Science and Innovation.

Thanks to the integrated use of Solid Edge and FLOEFD, JALVASUB can carry out future developments of HYCOGEN systems. These include applications in the naval sector and in other markets. “Having an integrated tool allows us to develop designs quickly and easily, reducing time to market” said Alvarez.